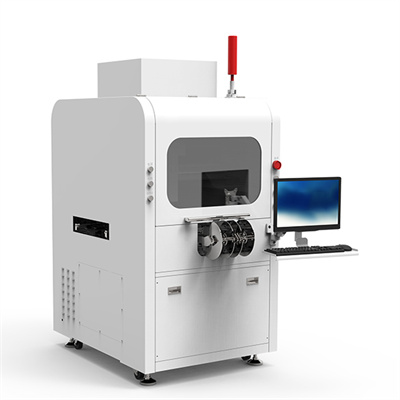

Fully automatic upper plane top suction and labeling machine

Technical Features:

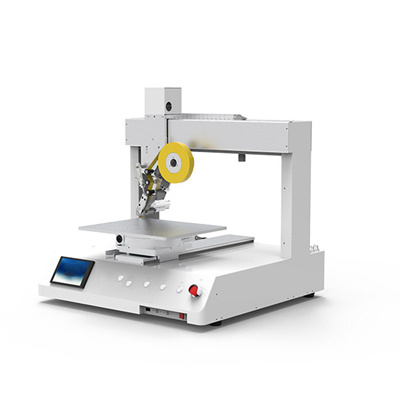

Roll-sticking process: Flatten the label by brush or sponge conveyor belt, suitable for large-area labeling, high efficiency but possible risk of bubbles.

Suction-sticking process: Utilize vacuum adsorption to achieve precise bonding, better bubble control, commonly used in high-precision scenarios (such as wafer film).

Visual positioning system: High-end models are equipped with CCD vision system to achieve micron-level accuracy (such as wafer dicing film machine) to meet the needs of the semiconductor industry.

Typical equipment: flat labeling machine, wafer film machine, UV irradiation film machine (for curing glue).

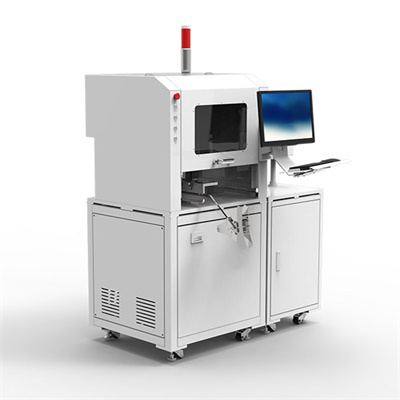

Round bottle equipment

Applicable objects: glass bottles, plastic bottles, cosmetic flat bottles and other cylindrical or conical products.

technical features:

Labeling method: support circumference, semi-circumference, double-sided and positioning labeling, through vertical or horizontal structure to adapt to different bottle types.

High-speed performance: The speed of the labeling machine can reach 500 pieces/minute, matching the steam shrinking machine to complete the label shrinkage and fixing, which is widely used in the beverage industry.

Typical equipment: round bottle labeling machine, labeling machinery, beer labeling machine.

Features: Adapt to a variety of types of equipment (such as mobile phones, tablets) by adjusting the tray, adsorption platform and positioning buckle.

Advantages: Low cost, strong compatibility, suitable for stores with complex equipment models.

Limitations: Manual adjustment of size settings is required, which may affect the efficiency and accuracy of the film.

Customized equipment

Features: Designed for specific equipment (such as a brand of mobile phones), the structure is highly matched.

Advantages: High film accuracy and strong stability, suitable for chain stores or brand franchisees.

Limitations: Poor flexibility, difficult to cover multi-device needs.