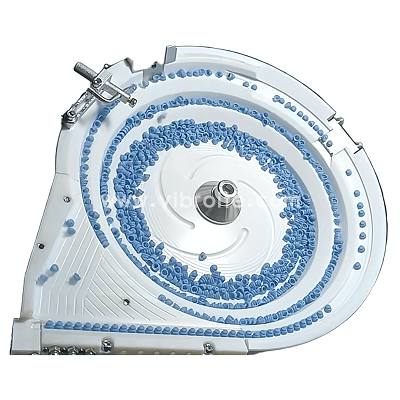

Vibroite CNC Black POM Vibratory Bowl Feeder for Bearings

The Vibroite CNC Black POM Vibratory Bowl Feeder is specifically designed for Ø22 mm bearing feeding applications. To meet the requirements of low noise operation and surface protection, the bowl is manufactured from CNC-machined black POM material, which significantly reduces operating noise and prevents damage to bearing surfaces compared to metal bowls.

With a 350 mm bowl diameter, the feeder provides excellent stability and is suitable for medium to high production capacities. The single bowl, single track design, combined with a linear vibratory feeder track, ensures consistent bearing orientation and smooth transfer to downstream assembly, pressing, or inspection systems.

A full-material auto-stop function is integrated to automatically stop vibration when downstream accumulation is detected, preventing jamming, stacking, and unnecessary wear.

The stable feeding speed ranges from 40 to 60 pcs/min, making it ideal for bearing assembly, inspection, and packaging automation.

Key Advantages of Vibroite:

Designed for Ø22 mm bearing feeding

CNC-machined black POM bowl for low noise and high wear resistance

Protects bearing surfaces from impact and scratches

350 mm large-diameter bowl for stable operation

Single bowl, single track configuration

Integrated linear feeder track

Full-material auto-stop function

Feeding speed: 40–60 pcs/min

Manufactured by Suzhou Vibrant Automation Co., Ltd.

The Vibroite CNC Black POM Vibratory Bowl Feeder is specifically designed for Ø22 mm bearing feeding applications. To meet the requirements of low noise operation and surface protection, the bowl is manufactured from CNC-machined black POM material, which significantly reduces operating noise and prevents damage to bearing surfaces compared to metal bowls.

With a 350 mm bowl diameter, the feeder provides excellent stability and is suitable for medium to high production capacities. The single bowl, single track design, combined with a linear vibratory feeder track, ensures consistent bearing orientation and smooth transfer to downstream assembly, pressing, or inspection systems.

A full-material auto-stop function is integrated to automatically stop vibration when downstream accumulation is detected, preventing jamming, stacking, and unnecessary wear.

The stable feeding speed ranges from 40 to 60 pcs/min, making it ideal for bearing assembly, inspection, and packaging automation.

Key Advantages of Vibroite:

Designed for Ø22 mm bearing feeding

CNC-machined black POM bowl for low noise and high wear resistance

Protects bearing surfaces from impact and scratches

350 mm large-diameter bowl for stable operation

Single bowl, single track configuration

Integrated linear feeder track

Full-material auto-stop function

Feeding speed: 40–60 pcs/min

Manufactured by Suzhou Vibrant Automation Co., Ltd.