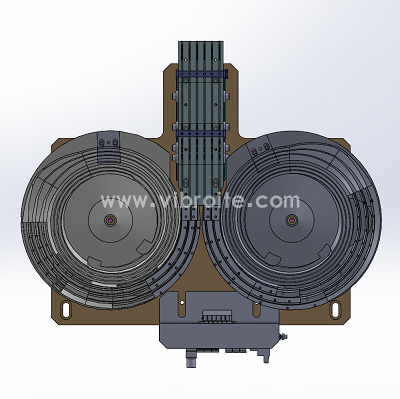

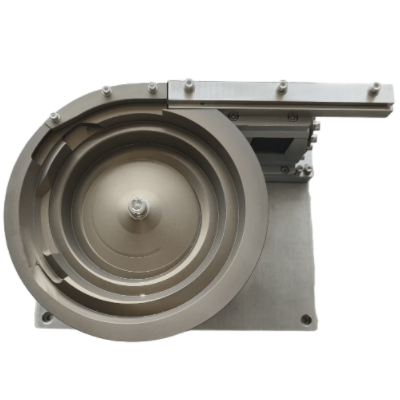

Vibroite Dual Bowl Vibratory Feeder for Plastic Parts with Dual Pins

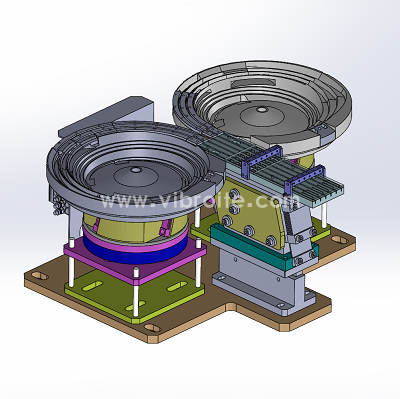

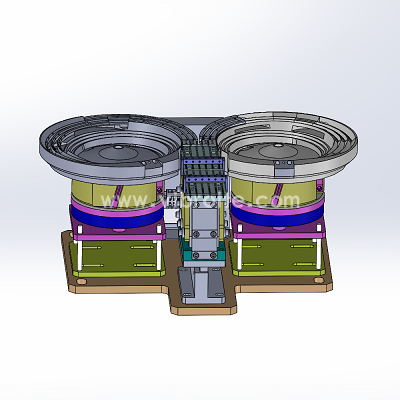

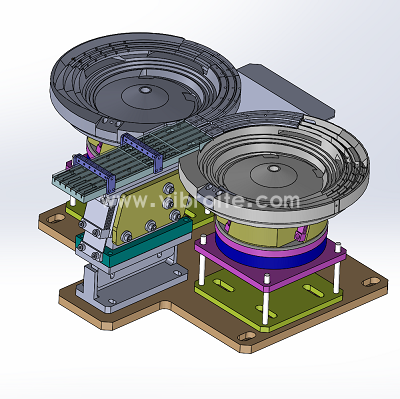

The Vibroite Dual Bowl Six-Outlet Vibratory Feeder is a high-capacity feeding solution specially developed for plastic parts with two pins. The system features two 240 mm diameter vibratory bowls, each equipped with three independent tracks, providing a total of six synchronized and stable outputs for multi-station automation.

To address the challenges of dual-pin plastic components—such as orientation sensitivity, pin jamming, and posture consistency—Suzhou Vibrant Automation Co., Ltd. integrates precision orientation mechanisms, sorting structures, and posture correction designs into the bowl tracks. This ensures consistent pin direction and smooth feeding even at high speeds.

The feeder can be seamlessly integrated with linear feeders, vision inspection systems, pin insertion machines, welding equipment, and automated assembly lines, making it ideal for high-throughput, multi-station production environments.

Configuration & Advantages (Vibroite Standard):

Bowl diameter: 240 mm × 2

3 tracks per bowl, total 6 outlets

Optimized orientation for dual-pin plastic parts

High-speed, stable feeding without interference

Supports pin detection, NG rejection, and vision systems

Compact structure, easy maintenance

Vibroite brand advantages: stable delivery, proven design, reliable service

The Vibroite Dual Bowl Six-Outlet Vibratory Feeder is a high-capacity feeding solution specially developed for plastic parts with two pins. The system features two 240 mm diameter vibratory bowls, each equipped with three independent tracks, providing a total of six synchronized and stable outputs for multi-station automation.

To address the challenges of dual-pin plastic components—such as orientation sensitivity, pin jamming, and posture consistency—Suzhou Vibrant Automation Co., Ltd. integrates precision orientation mechanisms, sorting structures, and posture correction designs into the bowl tracks. This ensures consistent pin direction and smooth feeding even at high speeds.

The feeder can be seamlessly integrated with linear feeders, vision inspection systems, pin insertion machines, welding equipment, and automated assembly lines, making it ideal for high-throughput, multi-station production environments.

Configuration & Advantages (Vibroite Standard):

Bowl diameter: 240 mm × 2

3 tracks per bowl, total 6 outlets

Optimized orientation for dual-pin plastic parts

High-speed, stable feeding without interference

Supports pin detection, NG rejection, and vision systems

Compact structure, easy maintenance

Vibroite brand advantages: stable delivery, proven design, reliable service