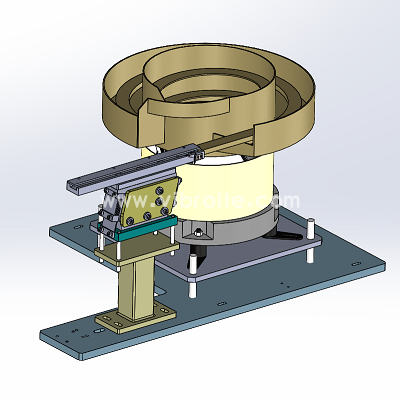

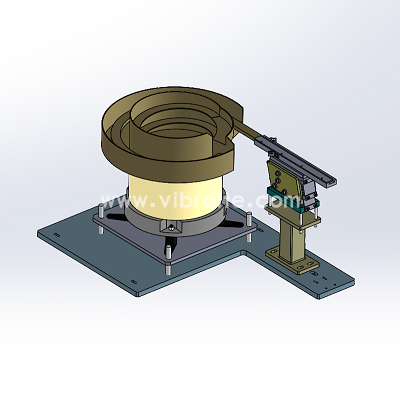

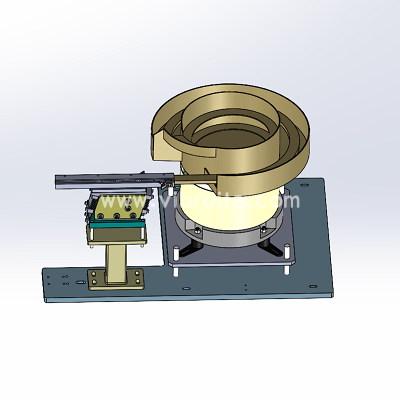

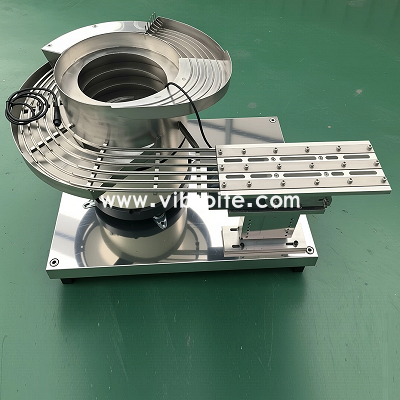

Vibroite Oil Return Valve Cap Vibratory Bowl Feeder

The Vibroite Oil Return Valve Cap Vibratory Bowl Feeder utilizes electromagnetic vibration to orient and sort large quantities of scattered valve caps along a spiral track. It ensures uniform orientation and smooth feeding into downstream automation equipment, supporting high-speed and stable production.

Considering the complex structure and easy-flip characteristics of oil return valve caps, Suzhou Vibrant Automation Co., Ltd. applies precision-machined customized tracks and anti-jamming mechanisms to guarantee smooth feeding during high-speed operation. The system can be integrated with linear feeders, vision inspection modules, and automated assembly stations.

This equipment is widely used in automotive components, hydraulic devices, plastic parts manufacturing, home appliance parts, and precision assembly industries, providing a reliable automated feeding solution for small and complex plastic components.

Features (Powered by Vibroite):

Specially engineered for oil return valve caps and similar parts

High-speed orientation with stable posture control

Vibroite wear-resistant and anti-impact track design

Supports automatic sorting, NG rejecting, and vision positioning

Customizable bowl track, feeding speed, and discharge direction

Designed for 24/7 continuous operation in mass production

Fast delivery, easy maintenance, and responsive technical support

The Vibroite Oil Return Valve Cap Vibratory Bowl Feeder utilizes electromagnetic vibration to orient and sort large quantities of scattered valve caps along a spiral track. It ensures uniform orientation and smooth feeding into downstream automation equipment, supporting high-speed and stable production.

Considering the complex structure and easy-flip characteristics of oil return valve caps, Suzhou Vibrant Automation Co., Ltd. applies precision-machined customized tracks and anti-jamming mechanisms to guarantee smooth feeding during high-speed operation. The system can be integrated with linear feeders, vision inspection modules, and automated assembly stations.

This equipment is widely used in automotive components, hydraulic devices, plastic parts manufacturing, home appliance parts, and precision assembly industries, providing a reliable automated feeding solution for small and complex plastic components.

Features (Powered by Vibroite):

Specially engineered for oil return valve caps and similar parts

High-speed orientation with stable posture control

Vibroite wear-resistant and anti-impact track design

Supports automatic sorting, NG rejecting, and vision positioning

Customizable bowl track, feeding speed, and discharge direction

Designed for 24/7 continuous operation in mass production

Fast delivery, easy maintenance, and responsive technical support