Vibroite Plastic Seal Ring Vibratory Bowl Feeder

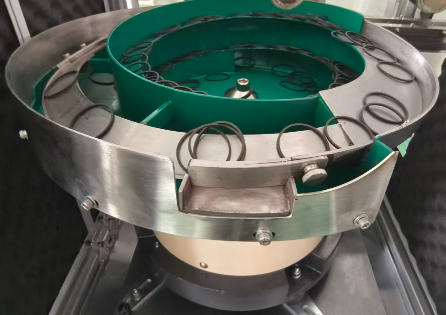

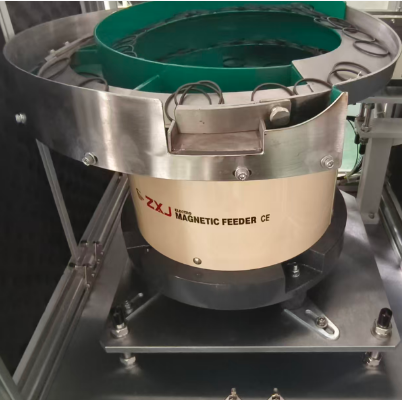

The Vibroite Plastic Seal Ring Vibratory Bowl Feeder is an advanced feeding system developed for circular seal rings, O-rings, and similar components. Powered by electromagnetic vibration, it automatically orients and elevates scattered rings along a spiral track, ensuring consistent and efficient feeding for automated production lines.

Suzhou Vibrant Automation Co., Ltd., with years of expertise in feeding system design, applies customized wear-resistant track treatments to prevent stretching, scratching, or deformation of the seal rings during high-speed feeding. The system can be seamlessly integrated with vision inspection machines, assembly systems, and packaging lines.

The Vibroite bowl feeder has been widely used in seal ring manufacturing, automotive parts, home appliances, and precision assembly industries, helping customers achieve stable, continuous, and high-efficiency production.

Key Features (Powered by Vibroite):

Specially designed for seal rings / O-rings with tangle-free feeding

Vibroite wear-resistant track protects material surfaces

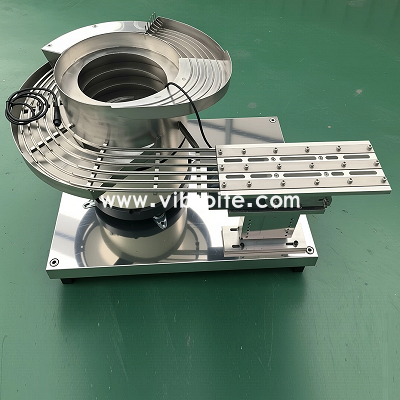

Customizable bowl size, track design, feeding speed, and output

Stable 24/7 continuous operation

Compatible with linear feeders, inspection systems, and assembly machines

Brand advantages: fast delivery, stable quality, and professional support

The Plastic Seal Ring Vibratory Bowl Feeder uses electromagnetic vibration to orient and elevate scattered seal rings along a spiral track, providing efficient and automated feeding for production lines.

The track is specially treated for wear resistance to prevent scratching, stretching, or tangling of the rings during feeding, ensuring a smooth and stable conveying process. The feeder is suitable for seal rings made of NBR, EPDM, silicone, Viton, and other materials.

It can be integrated with inspection systems, assembly machines, and packaging machines, making it an ideal feeding solution for seal ring manufacturers, automotive parts, household appliances, and industrial machinery industries.

Features:

Designed specifically for plastic / rubber seal rings and O-rings

High-speed and stable orientation, no tangling or jamming

Wear-resistant track for material protection

Supports orientation control, sorting, and inspection ports

Customizable bowl size, track design, and feeding speed

Compatible with automated production lines; supports 24/7 operation